What is the difference: LED Sign, Fluorescent Illuminated Sign and Neon Sign?

LED’s – The Way of the Future

LED’s are the way of the future, but for many of us the difference between them and more traditional light sources is a bit of a mystery. Mankind has always led a life that is surrounded by light, and where there is none, we find ways to develop a light source that suits our needs. We have come a long way since the discovery of fire, but new ways of lighting up our lives that are more energy efficient, cost efficient and that require less maintenance are continuing to evolve. LEDs are a great example of this evolution, and their use has infiltrated our daily lives from our remote controls to our televisions and of course our signage. There are 3 main types of lighting that we will discuss, these being: incandescent bulbs, fluorescent bulbs and LEDs.

Incandescent bulbs

Incandescent bulbs are light bulbs gives off their light through a process known as incandescence, where a wire filament is heated by an electric current with then causes the wire to emit photons. These photons are what you see as light. Incandescent lighting was invented in 1801 by the English chemist Sir Humphrey Davy. There were various types of incandescent lighting, but all of them were not very efficient. It was not until 1908 that the General Electric Company invented the first tungsten-filament incandescent bulb, this bulb was far more efficient that its predecessors. The efficiency was gradually increased using different inert gasses inside the bulb. The double coiled filament that we see today was not introduced until about 1930. Incandescent lamp. (2012). In Encyclopaedia Britannica. Retreived from http://www.britannica.com/EBchecked/topic/284597/incandescent-lamp

Incandescent bulbs are very energy inefficient, and for this reason incandescent bulbs are being phased out in most western countries. In Australia Tungsten Filament incandescent general lighting has been subject to a sales restriction since 1 November 2009. View climate change website for more information on lighting phase out.

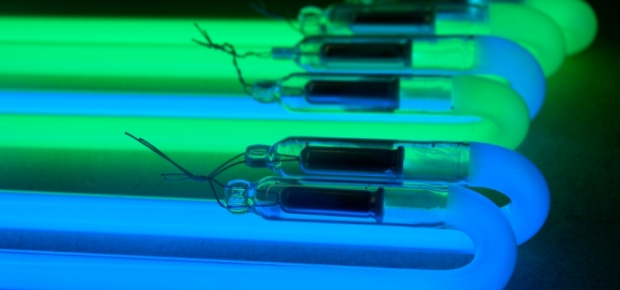

Fluorescent Lamps & Compact fluorescent lamps (CFLs)

The first fluorescent discharge lamps were produced by General Electric and the Westinghouse electric company in 1938. These fluorescent lamps used mercury vapour and phosphor-coated tubes, which enhanced the visible light output. This type of lighting is also knows as an electric discharge lamp, and is cooler and more efficient than its predecessor. The fluorescent tube is made of glass which is filled with a mixture of argon and mercury vapour. Metal electrodes are placed on each end. When electrical current flows from one end to the other through the gas, the result is ionized gas that emits ultraviolet radiation. The inside of the glass tube is coated in phosphorus and this absorbs the ultraviolet radiation and produces a fluorescence, which is seen as visible light. Fluorescent tubes don’t require continual heating of a filament as does incandescent bulbs, therefore they are more energy efficient, and cheaper to run. Fluorescent lamps though require a higher operating voltage when the lamp is turned on, as to ionise the gas. Therefore fluorescent lamps require a ballast, which supply the initial larger voltage and then maintain the lower operating voltage after the lamp has been switched on. Traditional fluorescent lamps have this ballast separately, whereas compact fluorescent lamps have this ballast nested into the cup at the base of the bulb assembly. Fluorescent lamp. (2012). In Encyclopaedia Britannica.

Retrieved from https://www.britannica.com/technology/incandescent-lamp

As fluorescent tubes had at least double the efficiency of the tungsten lamps there were rapidly adopted for commercial use. In traditional illuminated signs, traditional fluorescent tubes are used and produce a good quality product. It should be noted that this form of lighting requires more energy, and has a larger carbon footprint than LED’s and some other forms of lighting. View the light globe conversion table to compare incandescent bulbs and compact fluorescent lamps.

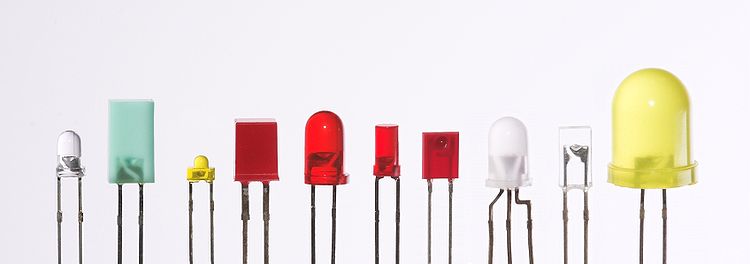

LED Signs

L.E.D stands for light emitting diode. An LED is a “semiconductor device that emits infrared or visible light when charged with an electric current.” Light-emitting diode (LED). (2012). In Encyclopaedia Britannica. Retrieved from http://www.britannica.com/EBchecked/topic/340594/light-emiting-diode There are 2 main types of LEDs – visible and infrared. LEDs are used in most of today’s electronic devices, for example billboards, alphanumeric displays, car brake and indicator lights, mobile phones, traffic signs, general lighting, autofocus cameras, remote controls and fibre optic telecommunication systems. Light-emitting diode (LED). (2012). In Encyclopaedia Britannica. Retrieved from http://www.britannica.com/EBchecked/topic/340594/light-emiting-diode Where other forms of light operate through luminescent and fluorescence, LEDs operate by electroluminescence. Electroluminescence is when the emission of photons is caused by electronic excitation of the material. The material that is most commonly used in LEDs is gallium arsenide. By varying the amounts and composition of these materials it is possible for LEDs to produce different wavelengths of light, that is colour. The voltage that is required for LEDs is quite low; therefore they are very energy efficient and cost much less than incandescent or fluorescent lighting to run. Light-emitting diode (LED). (2012). In Encyclopaedia Britannica. Retrieved from http://www.britannica.com/EBchecked/topic/340594/light-emiting-diode LEDs also don’t get hot like incandescent bulbs, therefore they can be used in many more applications. Their very small size also makes it possible for areas to be lit up that would not have previously been able to, using more traditional light sources. The life expectancy of an LED is up to 100, 000 hours, ensuring that it lasts many times longer than incandescent or fluorescent lamps. LEDs are certainly the way of the future and will continue to evolve and expand with the increases in technology. Although the initial outlay for LED’s can be more expensive, the cost is continuing to come down as technology and demand for the product increases.

Comparison chart – LED vs Incandescent vs CFL

More information on alternatives to incandescent lighting.

Examples of LED signs we have done.

LED signs for home and office.

Neon Signs or Cold Cathode lighting

Neon light was first invented by the French engineer and chemist Georges Claude in 1910. While he was studying inert gases (gases that will not readily mix with oxygen or other gases to form an explosive atmosphere, these elements make up group 18 on the periodic table and include: helium (He), neon (Ne), argon (Ar), krypton (Kr), xenon (Xe), radon (Rn), and element 118. These gasses are also colourless, odourless and tasteless. ) Claude discovered that if you pass an electrical current through these gasses that they will produce light. Different gasses produce different colours when an electrical current is passed through them – Helium – yellow, Neon – red, Argon – red or blue and krypton – yellow-green, xenon – blue to green.

The neon tube consist of an evacuated glass tube witch has electrodes attached to each end, a small amount of the required inert gas is added. The electrodes are then connected to a high voltage power source, which in turn makes the tube glow. Other colours can also be obtained by using coloured glass or coating the glass in phosphor powder. Once the glass tube is made is then bent by specialist neon benders into the desired shapes. One of the biggest draw backs of neon technology and neon signs is that the glass tubes that contain the gasses are very fragile and easily broken. Once they are broken they need to be replaced, as they cannot be repaired, therefore in some applications their use can be inappropriate and prove expensive. More in-depth information on neon and the process of its manufacture.

Benefits of LED sign technology

- One LED can display many colours

- Widest range of colours and hues

- Can be dimmed

- Energy efficient

- Low voltage

- Long life

- Small, compact and light

- Sealed unit

- Strong saturated colour

- Doesn’t contain mercury

- Very bright

- Relatively cost effective

- Very reliable

- Low head

- Very safe, as they only require 12V to run them

- Much easier to install

- Can be used for indoor and external applications

- Easy to service

- Easily transported

There are few disadvantages of LEDs over its competitors, these include: purchasing cost, not suitable for bare letter applications and that it doesn’t have a soft illumination like neon.